Presentation of our Bisontin partner Roland Bailly

In this article, we invite you to discover one of our Besançon partners: Roland Bailly.

Roland Bailly SAS is a company founded in Beure, in the Bourgogne Franche-Comté region in 1964. For 50 years, it has specialized in the production of precision tools but also in machining and the production of prototypes. Over the years, different departments have emerged within the company and have allowed a diversification of their know-how, which today allows Roland Bailly to carry out numerous operations in different sectors, notably that of watchmaking. In 1973, the company set up in Besançon, the cradle of French watchmaking, and began producing the first plastic injection molds for the watchmaking industry.

In 2001, a plastic injection workshop was created within the Roland Bailly company and it was from this moment that the activity in the field of high-end watchmaking was able to begin to develop.

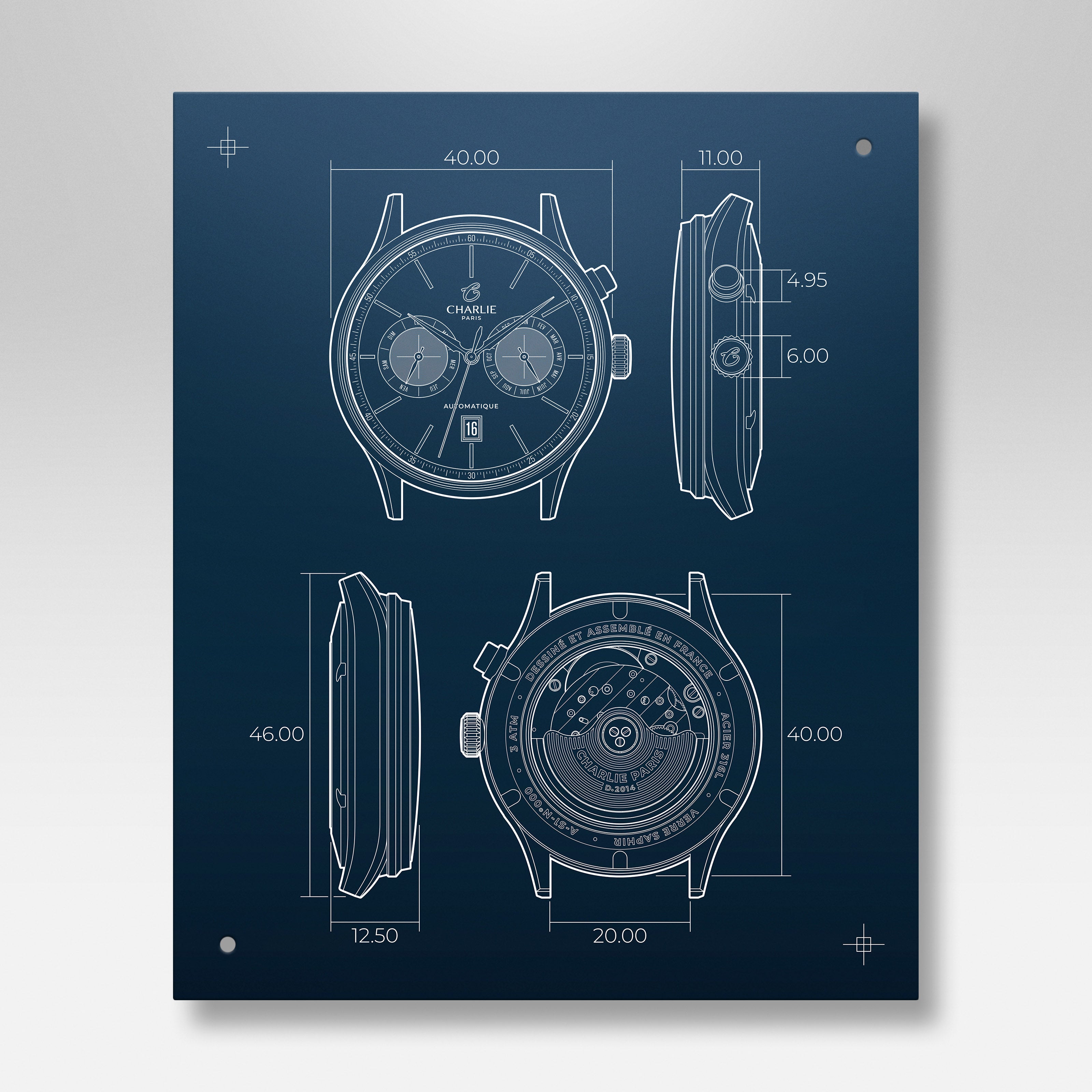

Charlie Paris x Roland Bailly

Today we have the opportunity to work with this industrial partner in the manufacturing of our G100 movements, present in our Alliance 68H models. More precisely, Roland Bailly takes care of the cutting and the openwork of our weight. To do this, the teams use a die-sinking electroerosion technique. Since the weight is made of solid tungsten, a very hard and very heavy metal, but also very resistant to corrosion, it is necessary to use this technique which allows the material to be pulverized extremely precisely. With this process, the opening of each of our masses takes around forty minutes.

This is a process that you can find in images on our YouTube channel. We had the chance to visit Thierry Bailly and his teams, and it was an opportunity for us to make a video retracing the steps of the openwork of our mass. We are proud to be able to collaborate with French companies like this one and thus highlight their know-how.

Focus on our Alliance 68h model, equipped with the G100 automatic movement from the Swiss manufacturer La Joux-Perret. This high-performance caliber guarantees a 68-hour power reserve and great precision, making the Alliance 68h an ideal choice for lovers of quality watches. Its 316L stainless steel case, with a diameter of 39.5 mm, is enhanced by polished and brushed finishes, with circular brushing on the bezel. Available in three refined colors, sage, white and blue, it is protected by a domed double-domed sapphire crystal, anti-reflective treatment, and a sapphire crystal case back revealing the caliber. Finally, its interchangeable strap system makes it a watch that is both elegant and functional for all occasions.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.