Beading, Beveling, Satin-finishing, Micro-blasting: the different watchmaking finishes

In watchmaking, there are different finishes that can be used to decorate the movements present in your watches. We tend to think that watch decorations are only used for their aesthetic side but we often forget their primary function: to hide small dust and particles that can lodge on the movement during machining. Indeed, their reliefs allow to capture dust but also to hide the traces of machining that could be left during manufacturing.

There are several types of finishes that we will be able to describe to you in this article.

Beading: a round decoration

Perlage is a watch decoration, easily recognizable thanks to its circular shape. Unlike the Côte de Genève finish which is placed on the wrist side, perlage is more discreet and is placed on two less visible areas: on the dial side of the movement and on the bottom of the plates. On the first area, the dial hides it and on the second, since the movement is closed by the bridges, it is hardly visible. However, this does not detract from the beauty or usefulness of this round decoration. Thanks to its circular shape, perlage is often used in the hollows of the movement because it is the only decoration that can be done in this kind of narrow place.

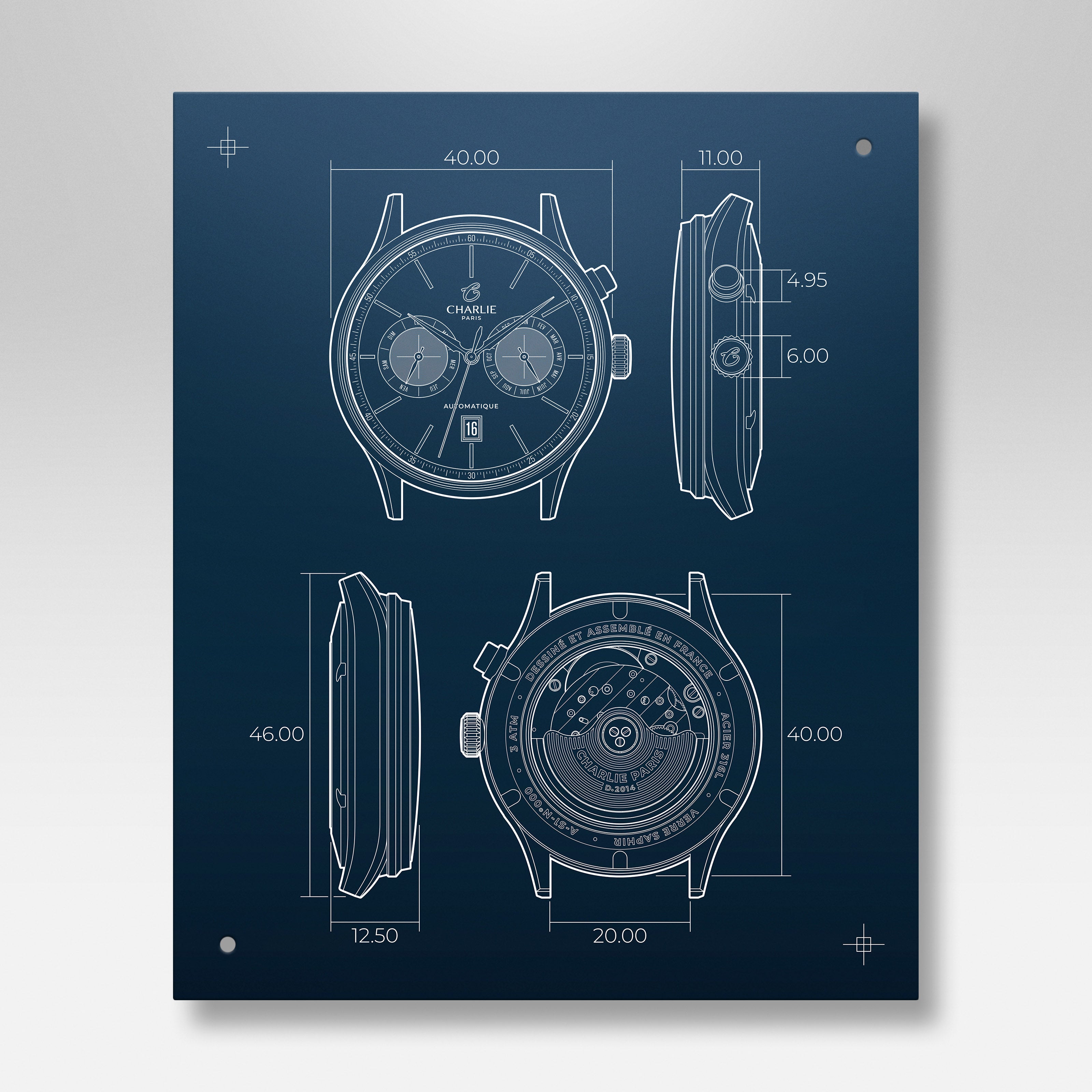

Find this decoration on our Alliance Phase de Lune Perpétuelle model and its C105 movement.

The Angle

Beveling is an extremely meticulous watch finishing process, which consists of removing the edges between the surface and the sides, as well as forming a polished bevel. As with all watch decorations, beveling removes any traces of machining that may have been left on the edges. These traces could harm the proper functioning of the mechanical movement, so it is essential to remove them. There are different methods used for beveling:

- Modern methods are defined by machining the parts. The chamfering is then carried out by milling machines and then the polishing is carried out chemically, mechanically or even with brushes.

- Then there are the artisanal methods that take much more time and require unique know-how and specific tools such as a burnisher, a wooden wheel and many others. Artisanal beveling is a rare and expensive technique these days.

This is a watch finish that you can find on our C105 and G100 movements, present in our Alliance models.

The Satin

Satin finishing is a decoration that you can find on certain watch movements. It is also called "drawn lines" or "drawing". This finish consists of covering a surface with a set of fine scratches, all parallel to each other. These reliefs then created will be able to catch the light and allow the movement to adopt pretty reflections, while giving a homogeneous appearance to the treated surface.

Microblasting

Microblasting is a watchmaking finish, which is defined by the treatment of a surface by impacts of glass beads. These micro-beads are then projected onto a surface in order to create slight impacts, without damaging the treated surface. This treatment is extremely versatile because depending on the size of the glass beads as well as the force with which they are projected, it is possible to obtain varied results.

Like all watch finishes, in addition to the aesthetic side, which makes the treated surface textured, this finish also helps to hide traces of machining.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.